Here are some of the services we can provide.

Free technical consultation

Are there any problems regarding heat treatment?

Do you have any problems or difficulties with your current quenching process?

Our technical staff are available for consultation.

[Consultation case]

- Q1. Troubled by heat treatment distortion with current heat treatment methods.

- Q2. I don’t know which process I should put heat treatment in.

- Q3. I don’t know the difference between induction high-frequency and laser-hardening.

Our technicians are happy to provide free advice on any subject as far as they can tell.

| Qualified person (As of July 2021) | |

|---|---|

| Metal heat treatment technician (Special grade) | 1 |

| Metal heat treatment technician (1st grade) | 10 |

| Metal heat treatment technician (2nd grade) | 3 |

| Metal material technician (2nd grade) | 2 |

| Laser processing management engineer (Honorary 1st grade) | 1 |

| Special safety training for industrial robots | 4 |

Free technical seminars

Use this as an opportunity to acquire technical skills and basic knowledge

Monthly Web seminars

Launched in June 2020, these monthly webinars are organised in collaboration with the laser equipment trading company Marubun Corporation. The following topics will be mainly explained. Basics, applications and trouble cases of laser-hardening and laser-cladding, as well as the configuration, maintenance, safety and trouble cases of equipment related to these technologies, which will be very useful information for customers considering laser hardening and cladding.

- Event date : Monthly

- Time : 1 to 2 hours

- How to apply : Please contact us via

- Instructor : Fuji Koushuha Industry Co.,Ltd / MARUBUN CORPORATION / other

Visiting seminars *Web seminars are also available

Our sales representatives will visit your company and hold a seminar. The content will be discussed with the person in charge and customised for your company. We hope you will make use of these seminars as a way of spreading knowledge of high-frequency and laser technology within your company.

- Event date : We will schedule sessions as requested

- Time : 1 to 2 hours

- Number of participants : At your convenience *We prefer a minimum of three participants.

- How to apply : Please contact us via

- Instructor : Fuji Koushuha Industry Co.,Ltd

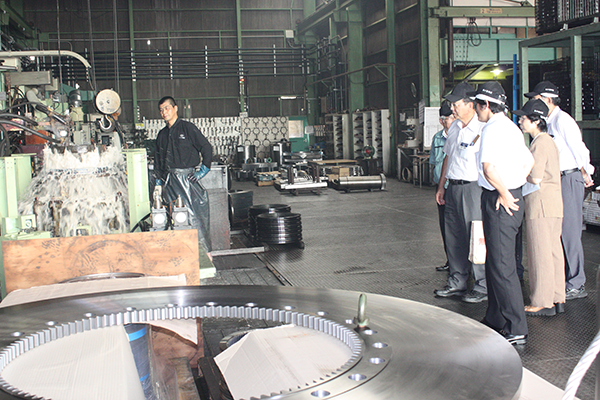

Company tour

‘Seeing is believing’ See it in action

Seeing is believing,” but the best way to understand our technology is to actually visit our factory rather than to explain it in words or documents. It will give you a better understanding of our technology. We invite you to visit our high-frequency division and laser division and, if you wish, we will also hold a technical seminar at the same time. As far as photographs and videos are concerned, we have no problem taking photos and videos of non-confidential content, as long as you ask us to do so. We will do our best to make the time spent with our engineers as meaningful as possible for you.

- Max number of people : 8 persons

- Required time : 1-2 hours. *Adjusted on request

- Entry fee : Free

- How to apply : Please click on the button below and send us an email with a request for a company tour.

Contract processing

From single items to mass production

Heat treatment and overlay processing are carried out on products received from the customer. We can handle all kinds of lots, from high-mix low-volume production to mass production. For mass-produced products such as automotive parts, we have an extensive quality control system, including heat treatment audits.

- Number of lots supported : 1-100,000pcs/month

- High-frequency Standard delivery date : 3 working days

- Laser-hardening Standard delivery date : 2 working days

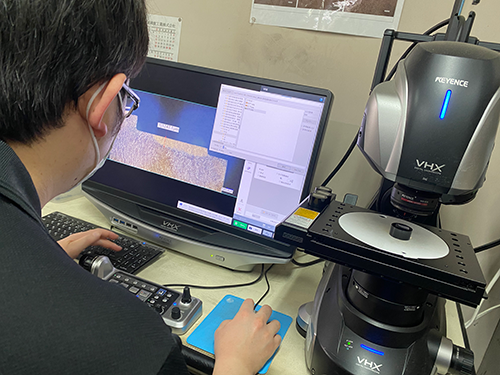

Prototype

Engineers’ know-how to meet customers’ challenges

We use the know-how we have developed over the years to produce prototypes to the satisfaction of our customers. We also have the equipment and many inspectors to carry out heat treatment inspections, and can quickly provide inspection results for metal heat treatment, such as surface hardness, depth of effective hardening layer and metallurgy.

List of inspection facilities

| Machine name | Manufacturer | Specs | Number of units |

|---|---|---|---|

| Rockwell Hardness tester | MATSUZAWA Co.,Ltd | Max height 250mm Total test load 60 / 100 / 150 Semi-automatic |

3 |

| Model-C Shore Hardness tester | Nakai Precision Machinery Mfg. Co., Ltd. | Dimensions W150xD162xH440mm | 3 |

| Equotip Bambino2 | PROCEQ | Impact testing machine Model-DL / Model-D | 3 |

| Fully Automated Micro vickers Hardness tester | Mitutoyo Corporation | Total test load 100 / 200 / 300 / 500 / 1,000g / 2,000g | 1 |

| Fully Automated Micro vickers Hardness tester (MH200) | Mitutoyo Corporation | Total test load 0.05g-2,000g | 1 |

| Ether Hardness tester | FTS., LTD. | Total test load 9.81N-98.07N | 1 |

| Instantaneous Flash Ultra Light (Black Light) | EISHIN KAGAKU Co.,Ltd | Power supply AC100V Input current 0.5A Lamp power 35W UV intensity 6000μW/cm2 |

2 |

| Horizontal Wet Magnetic Particle Testing Device (DM163) | Denshijiki Industry Co.,Ltd. | DC 2,000A AC 1,500A Max opening 400mm Contact surface 100 x 100mm |

1 |

| Handy Magna | EISHIN KAGAKU Co.,Ltd | Rated current 3A Total magnetic flux 0.70mWb Magnetomotive force 1900A Internal dimensions of the magnetic poles 140mm Removable variable universal yoke |

3 |

| Metallurgical microscope | Olympus Corporation | Magnification x 50-1,000 | 1 |

| Digital Microscope (VHX-7000) | KEYENCE CORPORATION | Magnification x 20-2,000 | 1 |

- Price : Calculated in prototype time

- High-frequency Standard delivery date : 7 working days

- Laser-hardening Standard delivery date : 5 working days

Witness prototype production

Confidence in the speed of post-construction inspections

For early-stage development projects, we carry out prototyping in the presence of the customer. You will observe the actual heat treatment site and discuss the prototype with our engineers. One of our strengths lies in the fact that we provide inspection results in the shortest possible time immediately after construction. Our extensive inspection equipment and inspectors are able to carry out inspections according to the customer’s requirements. During the witness prototyping, you are free to take photos of the construction conditions and set-up. To speed up the development process, we recommend that you carry out a witness trial production.

- Price : Calculation based on man-hours for witness time + man-hours for preparation time + man-hours for inspection outside of witness time

- Reservation required : Please contact us at least 2 weeks in advance

- Number of participants : Max of 6 people

Witness prototype production(Online)

Helping customers to reduce travel and other costs

This is a remote witness prototype using a web conferencing system such as ZOOM or Teams. You can see the situation during the construction process in real time via a webcam prepared by our company. We also guarantee speedy inspection results in the same way as for witnessed prototyping. This contributes to a reduction in travel costs, travel allowances and travel time. The price is the same as for a witness trial. Please feel free to request this service.

- Price : Calculation based on man-hours for witness time + man-hours for preparation time + man-hours for inspection outside of witness time

- Reservation required : Please book your preferred date at least two weeks in advance.

- Web tool : ZOOM,Teams,Webex, Other tools as specified by the customer can be used.